Fiber birefringence definition

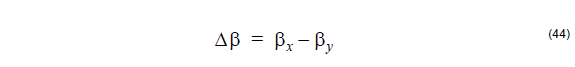

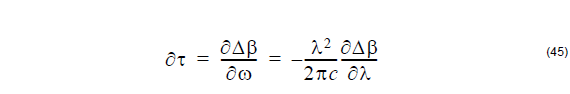

The birefringence is defined by the difference between the propagation constants of

the polarization Eigenmodes, that is:

The Differential Group Delay (DGD) per unit length is defined by:

Intrinsic perturbations birefringence

Intrinsic perturbations are accidentally introduced in the manufacturing process and

are permanent feature of the fiber. These include a noncircular core and

nonsymmetrical stress fields in the glass around the core region. A noncircular core

gives rise to geometric birefringence, whereas a nonsymmetrical stress field creates

stress birefringence. These results were obtained by the perturbation theory and

applied only for step index fibers.

Elliptical core birefringence definition

The geometrical anisotropy of a non-circular core introduces a linear birefringence in

the fiber. This birefringence depends strongly on the frequency, or on the normalized

frequency V, at which the fiber is being operated.

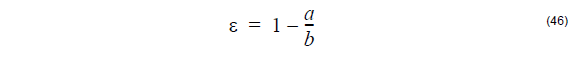

The non-circulatory or ellipticity of the core is defined by the parameter ε:

where a and b are respectively the minor and major axis of the elliptical core.

The birefringence induced by an elliptical core is linear. The fast axis and slow axis of

the birefringence corresponds respectively to the major and minor axis of the ellipse.

In the case of a step index fiber, the birefringence

is given by [Sakai and Kimura, 1981[17]]:

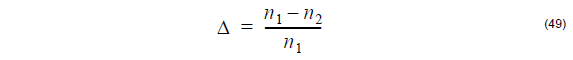

where

is the relative index difference between the core refractive index n1 and the cladding

refractive index n2.

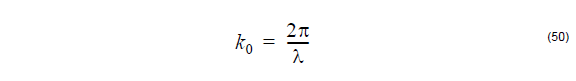

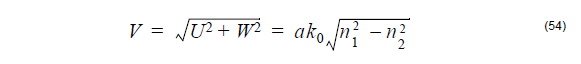

The wave propagation constant is

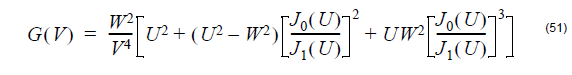

The function G(V) in the birefringence formula is given by

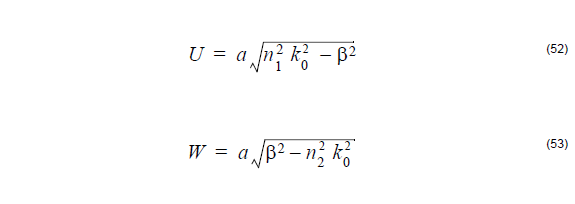

with the following definitions of waveguide parameters

where a is the core radius.

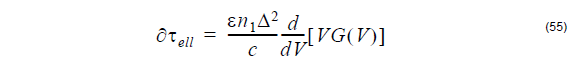

The Differential Group Delay (DGD) per unit length is

where c is the speed of light in vacuum.

Internal stress birefringence definition

Stress birefringence caused by a nonsymmetrical stress field in the core region of a

fiber typically arises in combination with noncircular fiber geometry. The necessarily

different chemical composition of the core relative to the cladding in single-mode fiber

usually results in a slightly different thermal expansion coefficient for the two regions.

This gives rise to radially directed stresses when the fiber is cooled after being drawn.

In an ideal, circularly symmetrical fiber, these stress fields are symmetrical and thus

do not cause anisotropy. However, if there is a noncircular shape to either the core or

the cladding in the preform, the drawn fiber will have internal stress fields that are not

circularly symmetrical.

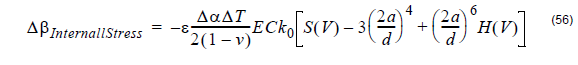

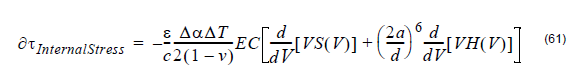

In a step index fiber with an elliptical core, the birefringence is given by [Sakai and

Kimura, 1982[18]]:

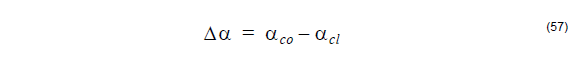

where

is the difference between the thermal expansion coefficients of the core αco and

cladding αcl

and

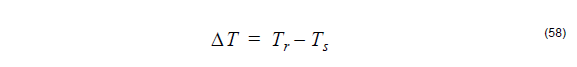

is the difference between the room temperature Tr and the softening temperature Ts

of the more heavily doped material.

The remaining symbols in the above internal-stress induced birefringence are:

ε – core ellipticity

v – Poisson’s ratio

E – the Young modulus

C – photoelastic constant

k0 – wave propagation constant in vacuum

a – the average core radius

d – the cladding outer diameter of the fiber

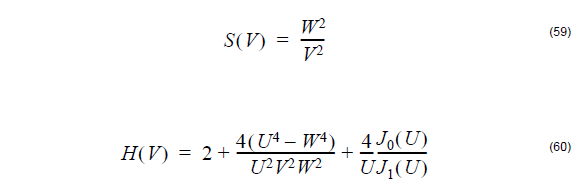

and

The symbols U,V, and W are defined in section: Elliptical core birefringence definition.

The Differential Group Delay (DGD) per length unit is given by:

Extrinsic perturbations birefringence

Birefringence can also be created in a fiber when it is subjected to external forces in

handling or cabling. Such extrinsic sources of birefringence include lateral stress,

fiber bending and fiber twisting. All three of these mechanisms are usually present to

some extent in spooled and field-installed telecommunications fiber.

Lateral stress birefringence definition

When two equal and opposite forces p act across an axis of a fiber with a diameter d,

the birefringence induced is linear. The fast axis of birefringence is aligned with the

axis defined by the two opposite forces.

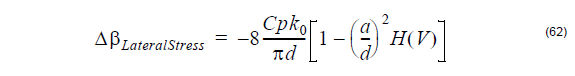

The birefringence is given by [Sakai and Kimura, 1981[17]]:

where

C – photoelastic constant

p – lateral force

k0 – wave propagation constant in vacuum

d – the outer diameter of the fiber

a – the average core radius

and H(V) was defined previously in the section: Internal stress birefringence

definition.

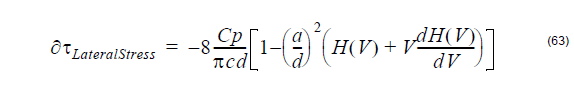

The Differential Group Delay (DGD) per unit length ∂τLateralStress is:

Bending birefringence definition

Bending on a fiber with a bending radius R >> a (fiber core) gives rise to a linear

birefringence. The fast axis of birefringence is perpendicular to the bending plane.

The slow axis is aligned with the bending radius.

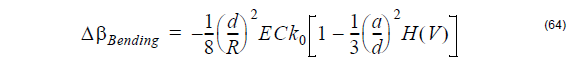

The birefringence is given by [Sakai and Kimura, 1981[17]]:

with R being the bending radius, and other symbols are:

d – the outer diameter of the fiber

E – the Young modulus

C – photoelastic constant

k0 – wave propagation constant in vacuum

a – the average core radius

and H(V) was defined previously in the section: Internal stress birefringence

definition.

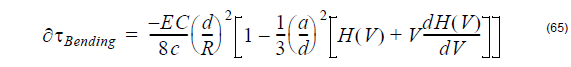

The Differential Group Delay (DGD) per unit length is:

Bending under tension birefringence definition

If we consider a pure axial stress applied to the fiber, simple symmetry considerations

show that there is no induced birefringence. But winding a fiber with axial tension f

onto a drum introduces an additional linear birefringence that adds to the bending

birefringence. This tension-coiled birefringence results from the lateral force exerted

by the drum on the fiber in reaction to the tensile force f.

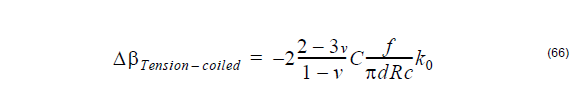

The definition is given by [Sakai and Kimura, 1981[17]]:

where

C – photoelastic constant

f – axial tension

k0 – wave propagation constant in vacuum

R – bending radius

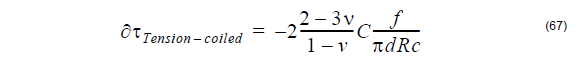

The Differential Group Delay (DGD) per unit length is given by: